Menü

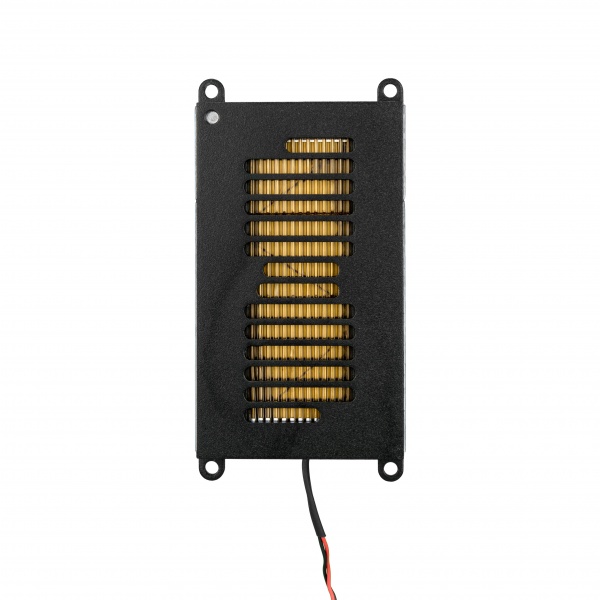

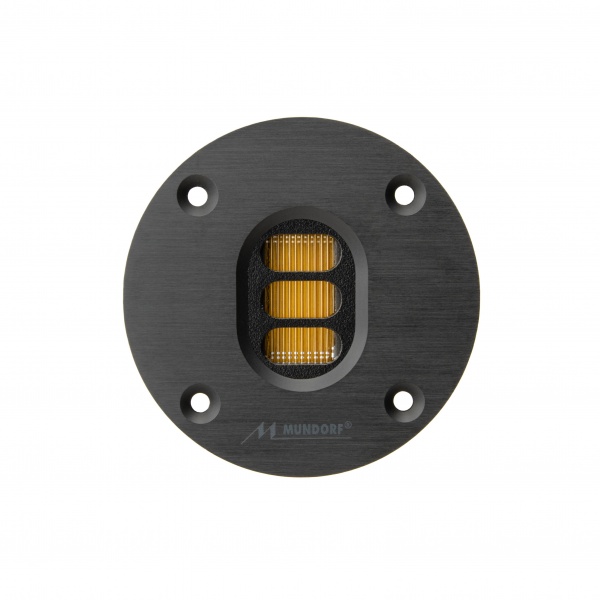

- Tweeters

- Capacitors

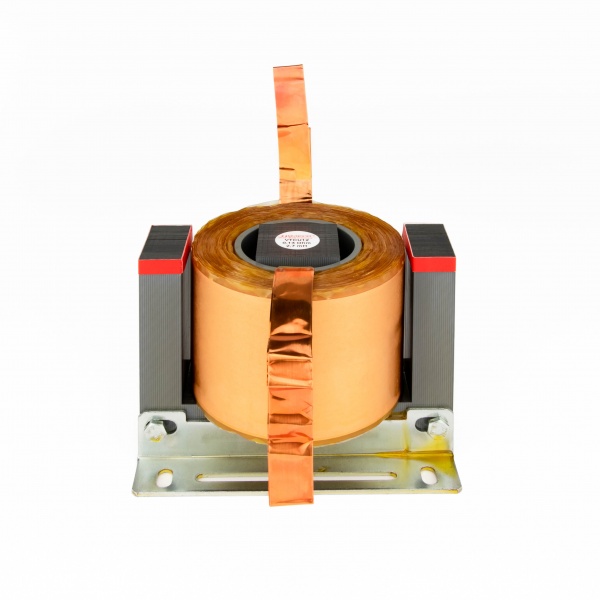

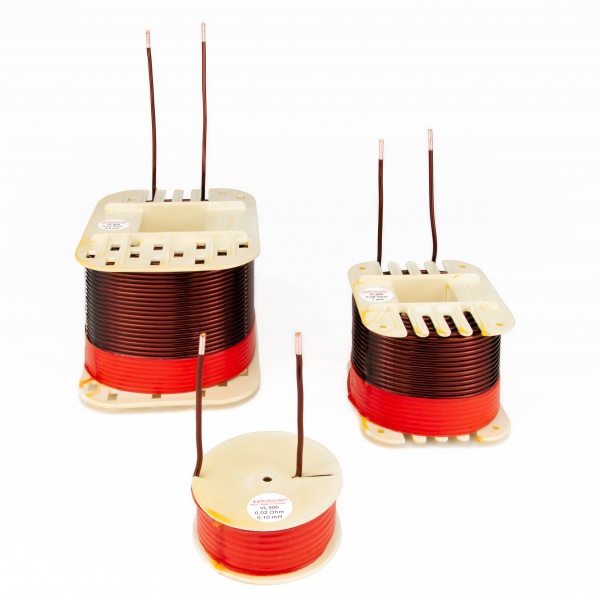

- Inductors

- Resistors

- Solders

- Damping

- Wires

- Terminals

- Dealers

- Customizations

- Highlightkategorie

.jpg)